Description

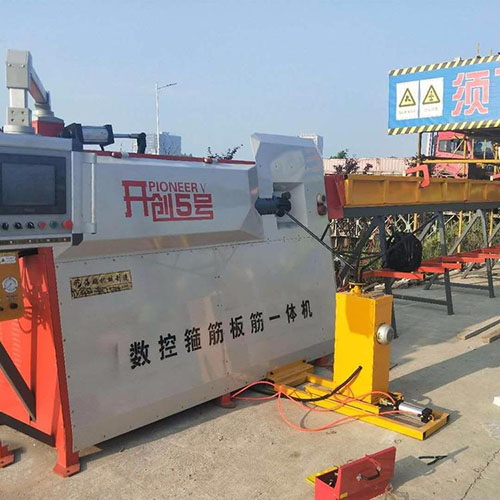

Rebar Hydraulic CNC Hoop Bending Machine

Steel Rebar Stirrup Bender / Hoop Bending Machine from feeding, descaling, straightening extends curved shape, cut a variety of processes single one alive, directly produced a variety of specifications of various sizes, fully meet the design requirements . A variety of specifications can be processed in various sizes square, rectangle , diamond, polygon, etc.

Steel Rebar Stirrup Bender / Hoop Bending Machine can automatically complete straightening steel , length, bend-shaping and cutting and other functions , saving time , high production efficiency can be achieved automatic , uninterrupted processing operation .

Steel Rebar Stirrup Bender / Hoop Bending Machine is widely used in railways ,highways , bridges , real estate, steel plants and other larges areas.

Stirrup bender properties: automatic straightening, bending and cutting in one shape.

Hydraulic Control

Accuracy<1mm

Bending shape>800

Max bending diameter 14mm

CHARACTERISTIC:

1.Automatic wire feeding system ( CNC ).

2.Moveable air compressor design, to ensure better cooling effect, easy transportation and installation

3.Split, multi-blade design to reduce consumption costs

4.Large storage capacity can save 500 processing geometric graphics, high degree automation

5.Automatic double wire intake system, high processing efficiency

6. High power feeding motor to ensure bending bar accuracy.

7.The intelligent fault identification alarm system maintenance more convenient

8. Aerodynamic design observation door, easy adjustment and maintenance, and more security and fast.

9.Heavy-duty design line planes, equipped with a brake and buffer device can prevent chaotic lines caused by downtime

10. High quality special material and high treatment to make straightening wheels, traction wheels, the metering wheel, longer life with lower operating costs

11. 12S type - Touch-screen pannel, easy to operate, and more fast

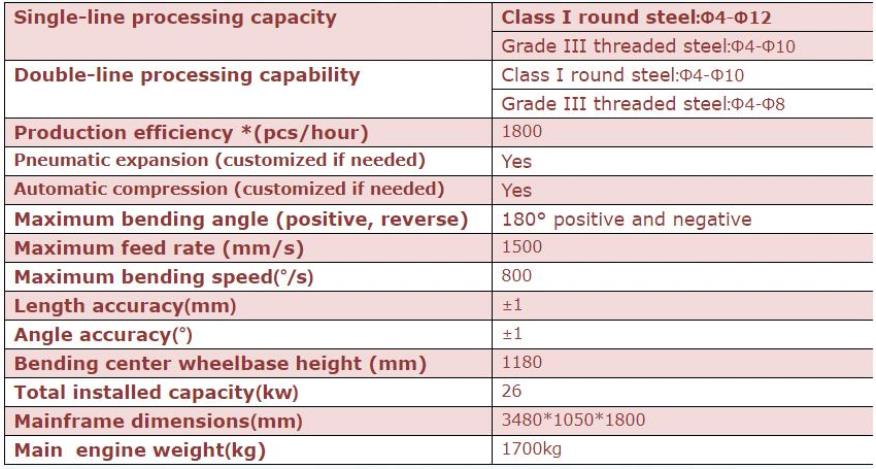

Parameters of Steel Rebar Stirrup Bender / Hoop Bending Machine for reference: